|

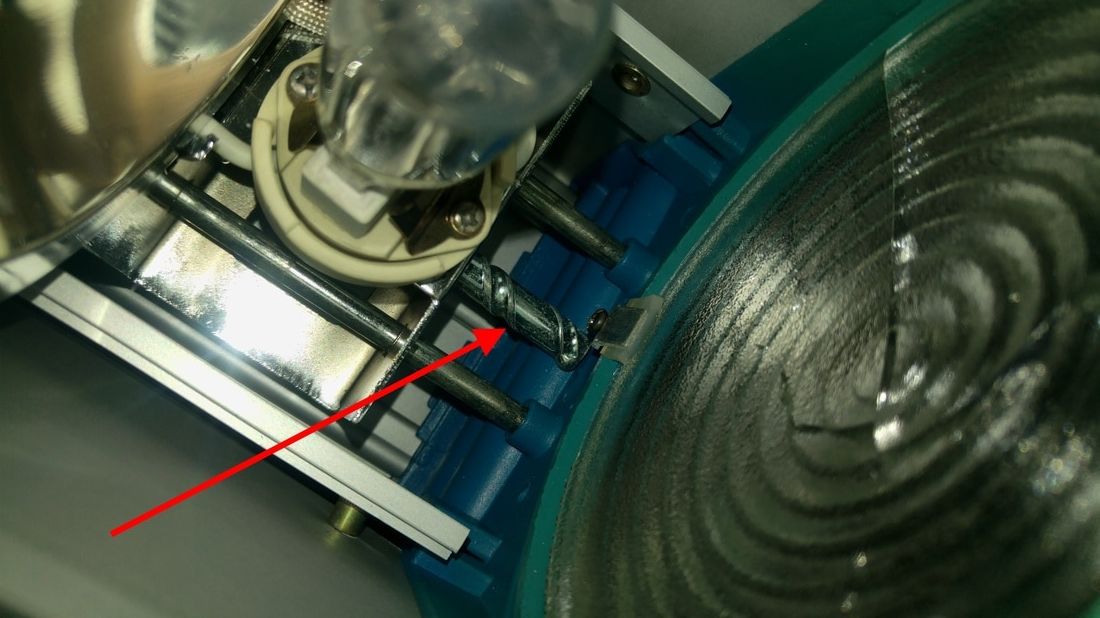

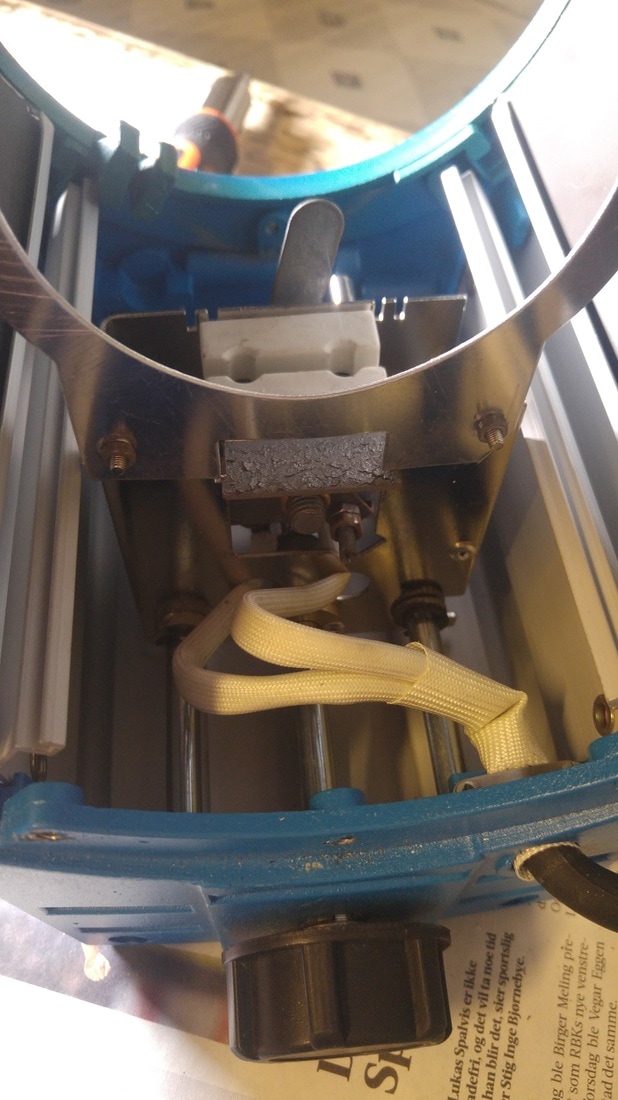

So I bought a kit of used Arri-like fresnel lights, stands and a softbox. I'm the third owner, and they had some wear, like a cracked lens on the 650w but nothing major, EXCEPT; I couldn't spot/focus two of the lights. I wasn't told this by the seller and was quite upset about it. But really what can you do? Shipping them back would have cost me so I'd rather try to sort it out. By the way, I barely know how to replace a bike tire. This is pretty much my first repair of anything ever, so if I could figure it out then anyone can! The culprit is the spot/focus system. As most of you are probably aware you spot/flood an arri fresnel with a knob on the back. In my case I couldn't really move the knob because it seemed the mechanism was stuck somewhere. I finally manged to move the element by pulling on it and turning the knob at the same time. Looking at some reviews of chinese copy-lights this seems to be an issue out of the box. Someone also mentioned somewhere a rod in theirs had bent. I really hoped that wasn't the case for me. I was betting on just having to grease it up a little. Greasing up the 1000W lightThis was the light with the most jammed spot/flood mechanism of them all, so if it worked on this one it would work on all of them. I bought some speciality synthetic grease made to withstand high temperatures. It's also transparent which is nice. Step 1Open up the front door. Then take out the bulb and dismantle the reflector. It's held by a screw on each side and a nut on the back. It was pretty tough holding the nut while screwing as I had to stick my pinky finger in there to add some resistance. If there is some sort of tool that makes this easier, let me know... Step 2Loosen the two screws located in the back top of the fixture. These connect the innter tube to the outer casing and the back plate. They come with a washer each. Step 3Remove the 5 screws connecting the large round backplate to the rest of the body. In this picture I had already removed two. Step 5Whip out your grease of choice. I called a few shops in my area, and this is what they recommended. I mostly chose it because it claimed high resistance to heat and cold and little spill. Also it's supposed to stay there and not evaporate. Being transparent was a nice bonus. Now find anything to apply with. I mostly used this brush used for greasing pans. A smaller thinner brush would have been better. Step 6Apply the grease. I sat tit to full flood, applied grease to all 3 rods, then full flood and did the same on the other side. As for the amount, use just enough to make a thin layer on top of the metal. In the end I tried greasing up the part in the middle as well, with moderate succes. But alas, suddenly I could move the knob! Also greased up the parts between the knob and main rod just in case. Did full flood/spot a few times to spread the grease and felt my body fill itself with happiness as my plan had worked! Step 7Put it back together the same way you opened it. I had two issues: First I wasn't able to attach the top back screws inside the fixture with the back plate and reflector up at the same time. So I ended up not putting them back in place. If it turns out to be an issue I will try again. 2nd issue was putting the back plate on. I had to push the aluminuim inwards a little while pushing it on. But it wasn't much of a problem really. I also let the light stay on for a couple of hours to see how the grease reacted to that. Still as good as before. I hope you found this helpful! If you have any further question feel free to comment or tweet at me @tonivuc! Keep in mind that I am not an electrician and I actually have no idea what I am doing. But it seems to work! Cheers!

1 Comment

2/11/2022 14:40:22

Behind get cause true successful popular. Audience marriage back piece. Start everybody term short professor.

Reply

Leave a Reply. |

AuthorI'm a freelance gaffer. I also do basic grip work. Archives

February 2020

Categories |

RSS Feed

RSS Feed